roller mill design

(PDF) Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 PDF An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agri-food, chemical,... Find,

Consulter un spécialiste

Selected Aspects of Modelling and Design

2021年3月1日 Quick design of new mill constructions, in particular for roller ones, requires the development of adequate mathematical models.

Consulter un spécialiste

(PDF) On the Optimization Procedure of Rolling

2012年9月27日 Rolling models serve as theoretical foundation of mill design. Two basic models – the force model and the crown/shape model

Consulter un spécialiste

Roller Mill - Springer

2023年7月4日 fl and the device for easy replacement. It can be divided into vertical roller mill, horizontal cylin-der roller mill, high pressure roller mill, Raymond mill, and column

Consulter un spécialiste

A study of operating parameters of a roller mill with a new design ...

2019年2月21日 The purpose of the study was to analyze and evaluate technical conditions of use of a roller mill with a new design (UPRP P.422676 and EP18460051) of the roller

Consulter un spécialiste

(PDF) A JOURNEY TO OPTIMAL ROLLING MILL

2011年9月14日 This article describes a scientific design procedure that begins from a given product mix to a customized rolling mill. The procedures were programmed into a pass schedule software package,...

Consulter un spécialiste

Digital Simulation and Performance Analysis on the

2017年8月25日 process characteristics of roller mill. The method of using virtual prototyping technology for roller mill simulation offers a new thought to design and further

Consulter un spécialiste

Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 The proposed research « Selected aspects of modelling and design calculations of the designed roller mills» falls within the scope of Sustainability. According

Consulter un spécialiste

A study of operating parameters of a roller mill

2019年2月21日 The new design of roller mill assembly consists of two rotating rollers with outer rings, between which a grinding plate is fixed permanently and the rollers are connected to drive shafts.

Consulter un spécialiste

Design and Realization Of Roller Mill Control System

2023年10月16日 Introduction Grinding materials is an important part for power generation, mining, and cement production process. The level of grinding efficiency and quality

Consulter un spécialiste

quadropol® vertical roller mill - thyssenkrupp

The roller unit has a very compact design, is fully pre-assembled in the thyssenkrupp proprietary workshop and is the final component to be installed. The vertical roller mill design calculation considers efficient

Consulter un spécialiste

(PPT) 04-03Raw (1) huong trinhvan - Academia

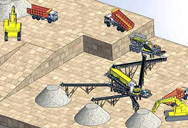

Sepriadi Sepriadi. Grinding/crushing is a process of reducing the size in a crushing plant to get the desired size. The coal ball mill technique is where the ball collides with the feed on the tube wall, thus cracks will form in the

Consulter un spécialiste

Industrial application of system integration updated

The vertical roller mill, also called vertical mill, which is widely used in the modern cement industry because it has high grinding efficiency, strong drying capacity and simple system configuration. ... Development State of VRMs in the World and Design and Operation of the LGMS4624 Model Slag VRM (I) [J]. Mining Processing Equipment, 2008 ...

Consulter un spécialiste

Modeling of energy consumption factors for an

2023年12月4日 80 mm. e raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill). e raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter ...

Consulter un spécialiste

Vertical Roller Mills - FLSmidth

Over recent decades, continuous advances in manufacturing processes and design principles have helped us to produce reliable vertical roller mills of ever-larger size and potential capacity. On November 11 2020, we held a webinar on the latest developments in operating and maintenance practices as well as new vertical roller mills innovations.

Consulter un spécialiste

A study of operating parameters of a roller mill with a new design

2019年2月21日 Structural design of a roller-plate mill unit with a plate inclined at angle α; 1 -grinding roller, 2 -sloped plate, 3 -milled material, 4 -plate deflection mechanism, D -roller diameter, -the ...

Consulter un spécialiste

Powder fineness to d = 10 µm PRINCIPLE OF

2020年6月9日 Typical ALPINE table roller mill characteri-stics: - Compact design - High throughput - Low energy consumption - Sharp top-size limitation of the products due to the fine/ultrafine classifier inte-grated into the top section of the mill. AWM table roller mills have proven them-selves in many field installations. Compared with ball mills, table ...

Consulter un spécialiste

Key Industry Program - Castolin Eutectic

2019年10月30日 Crack repair of Ball Mill Crusher with PTA wear facing On-site repair of Roller Press Our applications Based upon hundreds of successful applications approved by our clients across the globe, Castolin Eutectic can provide optimized solutions with a wide range of products and technologies to combat wear in VRM (Vertical Roller Mill) and

Consulter un spécialiste

Analysis and Optimization of Grinding Performance of Vertical Roller ...

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Consulter un spécialiste

Application of size reduction theory to roller mill design and ...

TLDR. Results showed that the most efficient way to increase flour yield in the eight-roller milling system is to increase the upper size limit of flour by increasing the sieve aperture, which is not followed by the deterioration of flour quality as determined by ash content. 10. PDF. 1 Excerpt.

Consulter un spécialiste

Yasuhiro Shigemoto, Hirofumi Kasai and Tatsuya

2020年7月17日 modular roller mill design, the same grinding roller modules are used for both raw and cement mills, and parts commonality is achieved. Furthermore, by matching mill power and table rotation speed, identical reduction gear units are used on the three VRMs: one set of 5-roller raw mills, and two sets of 6-roller cement mills.

Consulter un spécialiste

International Journal of ChemTech Research

2019年3月21日 1990; Audet, 1995). During roller milling each grain passes through the mill independently of surrounding grains (Campbell et al., 2001). For that reason, the breakage patterns for each grain depends mainly on the interaction between the grain, the roller mill design and operation conditions (Campbell and Webb, 2000).

Consulter un spécialiste

vertical roller Mill design principles and wearing parts repair ...

2015年4月29日 Roller是一种针对深度学习的快速高效的张量编译器。深度学习模型的训练和推断通常需要大量的张量计算操作,而传统的解释式执行方式效率较低。Roller的设计目标就是通过编译技术来提高深度学习中张量计算的效率。Roller通过将高级深度学习框架中的计算图转换为低级的、高度优化的代码来实现 ...

Consulter un spécialiste

study of operating parameters of a roller mill with a new

y x 3 2 4 FIGURE 3. Structural design of a roller-plate mill unit with a plate inclined at angleα; 1 – grinding roller, 2 – sloped plate, 3 – milled material, 4 – plate deflection mechanism,

Consulter un spécialiste

Roller Mill Based on Experimental Method - Semantic

2022年4月19日 3 Hefei Cement Research Design Institute Co., Ltd., Hefei 230601, China; dyy@hcrdi * Correspondence: [email protected] Abstract: This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments

Consulter un spécialiste

DRIVE SELECTION FOR LARGE LOESCHE VERTICAL

2017年8月12日 tem for a new, high-capacity vertical roller mill, and explains the thinking behind the decisions made. After a summary of the most important functions of the drive for a vertical roller mill, its design and design limitations, there is a detailed comparison, using a real project, to select the best available drive system.3

Consulter un spécialiste

OK™ cement mill The most energy- efficient mill for

2019年4月10日 The design combines the drying, grinding, material conveying and separation processes into just one unit, thus simplifying the plant layout. The OK mill incorporates unique patented design elements in the roller and table profile that improve operating stability and reliability, giving a typical availability of 90 to 95 percent of

Consulter un spécialiste

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane

Consulter un spécialiste

(PDF) Design and Realization Of Roller Mill Control System

2012年12月31日 a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT. The results demonstrate the practical application of ...

Consulter un spécialiste

(PDF) An approach to measuring and modelling the

2021年3月17日 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran. The model was calibrated using the initial survey's data, and the ...

Consulter un spécialiste

Article aléatoire

- rangkaian induksi moteur 3 phases untuk cruscher

- combien côté une pierre concasseur en Inde

- technologie de concassage de gypse

- concasseurs de materiel de traitement de cuivre

- formateur en traitement de minerai

- triturador de mais novo e mais barato

- coüt de machine de alimentation

- cuivreéquipements de concentre de minerai

- processus de concassage et de broyage

- écrasant l'action simple et double mâchoire à bascule

- pour acheter concasseur de pierre

- travailler vedios c106 concasseur

- phoeni projet de concasseur avis de la compagnie minière de newmont

- rocher Canada de traitement de zinc

- durable raymond machine de moulin broyeur 3r

- de pierre transporteur

- usine de pierre concasseur dan shapping

- ligne complète de meunerie

- agent de broyage de ciment msds

- esquema de montagem de linha de britagem

- finesse de broyeur à boulets

- gypse ligne poudre de plâtre en Allemagne

- ciment rapport de processus de moulins

- niveau de bruit dans le concassage de pierres unité

- broyeur à boulets broyage fournisseurs de minerai de fer

- moulin à moulin du sol australie

- concasseur à marteau l&039;argile

- équipement de detection de l'or en France

- Graviti électrique moulin à sel

- installation de broyage carbonate de calcium