Roller Mill Iron Ore

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 The application of vertical-roller-mills (VRM’s) for ore grinding is part of the second strategy. The grinding parts of a Loesche mill ( Fig. 1) are a rotating table (1) with

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results

Consulter un spécialiste

Roller Mill - Springer

2023年7月4日 fl and the device for easy replacement. It can be divided into vertical roller mill, horizontal cylin-der roller mill, high pressure roller mill, Raymond mill, and column

Consulter un spécialiste

An energy based comparison of vertical roller mills and tumbling mills ...

2015年3月10日 It is long established in the cement industry and gains more and more importance in the industrial mineral and iron ore sectors. In order to address the energy

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill - 百度学术

Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test

Consulter un spécialiste

Operational parameters affecting the vertical roller mill

2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry. Grinding test

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill - CEEC ...

2023年11月9日 Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results

Consulter un spécialiste

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries. In this study, the discrete element method

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 Research of iron ore grinding in a vertical-roller-mill Semantic Scholar DOI: 10.1016/J.MINENG.2014.07.021 Corpus ID: 109087773 Research of iron ore

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a vertical-roller-mill Find, read and cite all the research you need on

Consulter un spécialiste

High-Pressure Grinding Roller Presses for Minerals

2020年3月17日 Redevelopment of the large mill line 2012 Introduction of HYBRIDUR® wear protection with studded linings Improved design: MHF – Multi-Hinged Frame 2013 First HPGR delivered for iron ore pellet feed 2014 New HPGR machine sizes introduced ranging from 1.0m to 2.54m roller diameter 2018 More than 880 roller presses supplied to 68

Consulter un spécialiste

Operational parameters affecting the vertical roller mill

2017年4月1日 Recent installations and developments of loesche vertical roller mills in the ore industry. Comminution’12 Proceedings, Cape Town, South Africa (2012), pp. 1-22. Google Scholar. ... Research of iron ore grinding in a vertical-roller-mill. Miner. Eng., 73 (2015), pp. 109-115. View PDF View article View in Scopus Google Scholar. Roy, 2002.

Consulter un spécialiste

Why is vertical roller mill-based dry grinding not used in iron ore ...

2023年3月6日 Vertical roller mills (VRM) are commonly used in the processing of iron ore for dry grinding for several reasons: vertical roller mill Energy Efficiency: VRMs are known for their energy efficiency.

Consulter un spécialiste

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 G.G.O.O. Uwadiale. Starting from a crude ore assaying 45.6% Fe, a fine-grained oolitic iron ore was concentrated by the oil agglomeration technique to 90% Fe recovery and 65% Fe assay. The ore ...

Consulter un spécialiste

Roller Mill SpringerLink

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). ... and by 2015 it had been widely used in various metal and non-metallic minerals such as iron ore, manganese ore, cement raw clinker ...

Consulter un spécialiste

Roller Mill - Springer

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the ...

Consulter un spécialiste

Modeling and simulation of green iron ore pellet classification

2018年6月1日 The work analyzes the performance of the main type of screen used in classification of green iron ore pellets, the roller screen, through simulations using the discrete element method. Recognition of the sticky nature of the material led to the choice of the Hertz-Mindlin model with JKR cohesion to describe the contacts.

Consulter un spécialiste

Impact of key parameters on the iron ore pellets roller

2022年3月18日 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, Sept-Îles, QC, Canada 2 Minerai de Fer du Québec, 1100, Boul. René-Lévesque Ouest, Suite 610, Montréal, QC H3B 4N4, Canada * e-mail: agandrade@metal7 Received: 18 March 2022 Accepted: 5 May 2022 Abstract. The roller screening process is an important step

Consulter un spécialiste

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 A study conducted by Gerold et al. (2012) showed that VRM was able to grind copper and slag with the energy saving of 22.9% and 34.4% respectively compared to conventional grinding circuits. Wear rate is another criterion that is needed to be considered. In this context, Erkan et al. (2012) in their study compared the wear rates of rod-ball ...

Consulter un spécialiste

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

Consulter un spécialiste

LOESCHE vertical roller mills for the comminution of

2001年10月1日 The application of vertical roller mills (VRMs) for ore grinding is a part of the second strategy [1]. In the mid 90's, LOESCHE introduced its VRMs with the 2+2-technology for grinding clinker and ...

Consulter un spécialiste

Operational parameters affecting the vertical roller mill

2017年4月1日 A cement Vertical Roller Mill modeling based on the number of breakages. Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energy-intensive grinding

Consulter un spécialiste

Review on vertical roller mill in cement industry its

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed. ... Wang et al. 2009, Ghalandari et al. 2021)), coal (Tontu 2020), iron ore (Reichert et al. 2015), zinc ore (van Drunick et al ...

Consulter un spécialiste

Roller crushers in iron mining, how does the degradation of

2021年4月1日 Currently, in the mining process, roller crushers have been playing an important role due to their high productivity displayed in iron ore mining, as an example is an iron ore mine with friable hematite lithology and among others with uniaxial compression resistance of up to 200 MPa and Bond abrasiveness of up to 0, 37 g.

Consulter un spécialiste

Trends in der Minenindustrie - Mineral Processing

Today, HPGRs are some of the most important types of mill in the mining industry. From the market leader thyssenkrupp alone, so far more than 130 roller crushers have been sold for a range of different applications, such as grinding diamond ore/kimberlite, iron ore or iron ore concentrate and metal ores (hard rock).

Consulter un spécialiste

Grinding process within vertical roller mills: experiment and ...

2009年1月1日 A cement Vertical Roller Mill modeling based on the number of breakages. Wang, Chen et al. 2009 use a matrix model to replicate the grinding process in VRMs. It was developed based on experimental data from cement clinker, coal grinding lines, and laboratory experiments [15]. VRMs are simulated using high-efficiency classifiers, matrix

Consulter un spécialiste

Iron Ore Concentrate Particle Size Controlling Through

2018年10月8日 Nowadays, the HPGR (high-pressure grinding rolls) is an intermediate step between filtering and balling in the most modern iron ore pelletizing operation. The operation debottlenecks filtering process and reduces pressure over the typical milling process to control particle size to the balling. The present study evaluated aspects of microwave

Consulter un spécialiste

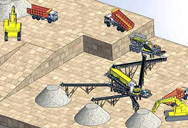

Iron Ore Processing, General SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

Consulter un spécialiste

Ball Mill for Sale Mining and Cement Milling Equipment

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher, flotation machine, concentrator, filter press. Auxiliary equipment: Linear vibration screen, cyclone.

Consulter un spécialiste

Iron ore vertical roller mill_Vertical roller mill

A Iron ore vertical roller mill is a specialized equipment used for grinding and processing Iron ore into Iron ore powder. Iron ore powder is a kind of ore powder processed by iron ore through benefic. HOME; ABOUT Company profile. TongLi History of Development. Machines Equipments.

Consulter un spécialiste

Article aléatoire

- tph pierre prix de revient de l usine de concassage

- jose pour le minerai de Concasseur à cone

- comment est le processus de la medecine de meulage

- processus de fusion de fer en tunisie

- Dimond rio broyeur de roche

- recherche concasseur occasion en algérie

- les mines de charbon sociétés indonésie

- la val'orisation de la production de fer concentré

- surface de calcaire liste de prix de Minner

- processus de la production totale

- rectifieuse pour faire la poudre de calcium

- céramique usine de broyage à billes

- de traitement de minerai de fer techology

- pierre mobiles de concassage

- mines de phosphate jordan co plc

- moulin à meule ligne de production de poudre de calcium

- taille moyenne de Raymond moulin

- comment l'installation de l'usine de concassage de la société de consruction

- boules de fer pour le broyage du Ciment

- machine de recyclage de la construction

- concasseur de roche utilisé de fabrication de sable

- pierre bouchon de broyeur t heure

- broyeur pour le charbonéquipement de Concassage

- concasseur de minerai de fer

- pelles minières prix

- Petite échelle la machine de fabrication de sable

- des usines de traitement de l or

- couronne pour broyeur a boulets

- dijual broyeur de pierres 250x400 shan arc

- équipement de separartor de fer de sable